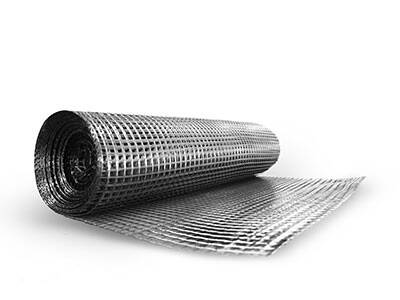

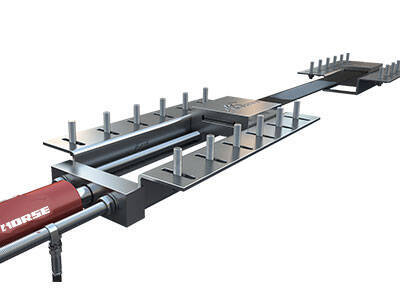

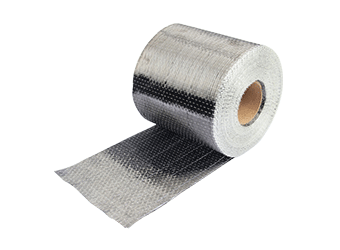

Solutions

La gamme d'activités Horse Construction a tendance à partout dans le monde et à servir des milliers de clients avec des produits, des conseils techniques spécialisés dans la construction, et nous assistons avec eux à la refonte de la marque chinoise.