Maladie et renforcement du pont mixte en acier existant

Le pont à poutres mixtes en acier existant est insuffisant ou le niveau de charge doit être augmenté, la méthode de renforcement par précontrainte ou collage de tissu en fibre de carbone (PRFC) peut être utilisée

Analyse de la maladie d'un pont mixte en acier existant

La capacité portante du pont est insuffisante et ne permet pas de répondre aux exigences de charge de trafic existantes.

Corrosion des poutres en acier nues

Fatigue des poutres en acier

Fissuration longitudinale de l'aile en béton d'une poutre continue mixte acier-béton

Fissuration transversale de la dalle de tablier en béton dans la zone de flexion négative d'une poutre continue mixte acier-béton

Rupture partielle ou corrosion du tablier en béton

Coupure de la liaison de cisaillement

D'autres problèmes liés à une faible charge de conception initiale sont la facilité avec laquelle les boulons et les rivets d'assemblage peuvent être remplacés ou renforcés en raison d'une surcharge et d'une exposition prolongée à l'air humide et à la pluie, ce qui peut facilement les desserrer ou les casser. Ces dernières années, l'utilisation intensive de sels de déglaçage dans les régions froides a gravement endommagé les installations auxiliaires, telles que le tuyau de drainage des joints de dilatation des poutres mixtes acier-béton. L'absence d'entretien régulier rend l'état du pont moins visible. L'âme ou le plancher de la zone de compression de la poutre en acier peut être affecté par une surcharge ou un échauffement accidentel. Des instabilités locales apparaissent, entraînant une instabilité locale. Si cette instabilité locale n'est pas corrigée à temps, elle réduira également la résistance de la structure globale à l'instabilité et, indirectement, sa capacité portante.

Stratégie de renforcement et de réforme

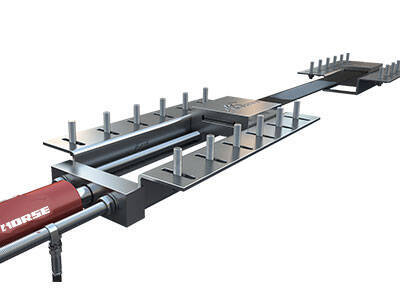

Armatures précontraintes externes

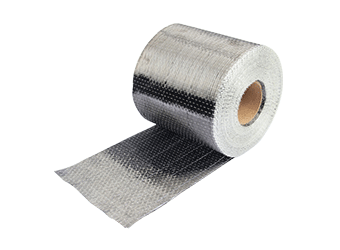

Fibres renforcées de fibres de verre collées extérieurement

Réparation de fissures ou de défauts de corrosion sur poutres en acier

Remplacement de tabliers de pont en béton

Modification de la liaison au cisaillement

Traitement de l'instabilité partielle des plaques d'acier

Résumé

(1) Les problèmes les plus courants et les plus fréquents des ponts à poutres mixtes acier-béton existants sont les suivants : la corrosion, la fatigue, l’accumulation de contraintes importantes et les contraintes résiduelles de soudage provoquent l’apparition de fissures dans les éléments des poutres en acier, entraînant leur rupture fragile. La structure et le procédé de construction spécifiques des ponts à poutres mixtes acier-béton provoquent la fissuration de la dalle du tablier et sa fissuration longitudinale dans la zone de moment négatif du pont à poutres continues mixtes. Endommagement et corrosion localisés du tablier en béton ; rupture par cisaillement.

(2) Les recherches existantes montrent que lorsque la capacité portante d’un pont à poutres mixtes acier-béton existant est insuffisante ou que le niveau de charge doit être augmenté, la méthode de renforcement par précontrainte ou par collage de tissu en fibres de carbone peut être utilisée in vitro. Ces deux méthodes permettent d’améliorer efficacement la capacité portante des ponts à poutres mixtes acier-béton armés existants, et cette augmentation est généralement obtenue.

(3) La liaison au cisaillement est essentielle pour assurer l’assemblage de la poutre en acier et du tablier en béton. En cas de dommage dû à la fatigue ou à un cisaillement longitudinal excessif, il doit être remplacé. Dans le cas contraire, l'action combinée des poutres mixtes acier-béton sera perdue et la structure se dégradera, réduisant ainsi sa capacité portante.

(4) Le pont à poutres mixtes acier-béton présente les mêmes problèmes que les structures en béton armé et en acier, tels que la corrosion ouverte, endommagée et des poutres en acier, les fissures de fatigue, le tambour et d'autres affections du tablier en béton, ainsi que des problèmes spécifiques. Par exemple, les problèmes de fatigue et de cisaillement de la liaison au cisaillement doivent être analysés spécifiquement pour les affections du béton. Une stratégie de renforcement ciblée est ensuite adoptée pour atteindre l'objectif de renforcement.