Avantages des ponts composites FRP

Le composite FRP présente les avantages d'un poids léger, d'une résistance élevée et d'une forte résistance à la corrosion, ce qui en fait un substitut à l'acier et aux câbles précontraints dans les ponts en béton. Avec la diminution du coût de l'industrie des composites à fibres, l'échelle de son application dans l'ingénierie structurelle des ponts continuera de s'étendre.

En raison des exigences structurelles et de maintenance des ponts, notamment en matière de sécurité, d'applicabilité et de durabilité, les ponts présentent, par rapport aux autres structures, des caractéristiques de construction suivantes : non-répétabilité, incapacité à effectuer des essais de charge complets, environnement complexe, extrême, longue durée de vie, contraintes et grande quantité. Ces exigences spécifiques confèrent aux matériaux composites de meilleures perspectives d'application en ingénierie des ponts.

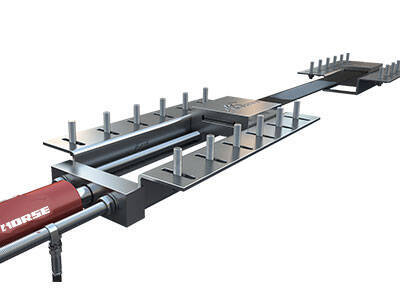

1. Montage rapide

La construction de ponts composites peut considérablement accélérer. Leur application aux viaducs, ponts, ponts urbains isolés et à la rénovation de ponts présente des avantages économiques et sociaux considérables. De plus, ils offrent d'importantes perspectives d'application pour améliorer la capacité d'intervention d'urgence et la réactivité après sinistre.

2. Forte résistance à la corrosion

Les fibres et les matériaux de matrice des matériaux composites sont tous des matériaux non métalliques résistants à la corrosion. Leur utilisation dans les structures permet d'éviter tous les risques et pertes liés à la corrosion et à la destruction. La corrosion et la détérioration des structures traditionnelles sont très graves, affectant non seulement l'utilisation normale et la durée de vie des ponts, mais aussi de nombreux risques de sécurité et d'accidents. La résistance à la corrosion des ponts composites garantit leur fiabilité à long terme. Elle améliore la sécurité de la structure et réduit les investissements en maintenance et en exploitation. Le matériau composite offre des couleurs vives et durables et ne nécessite aucun entretien particulier. Il est donc adapté à la construction de ponts paysagers.

3. Résistance à la surcharge et à la fatigue

La conception des ponts traditionnels, grâce à sa ductilité et sa capacité de déformation, permet d'obtenir une structure de sécurité. Les propriétés mécaniques des composites sont élastiques linéaires. La capacité portante est essentielle pour la sécurité. La capacité portante pratique des ponts composites est supérieure à celle des ponts traditionnels. De plus, le matériau composite ne subit pas de déformation plastique avant déchargement. Par conséquent, même en cas de surcharge, il retrouve son état initial, sans impact significatif sur son utilisation. De plus, la résistance à la fatigue du matériau composite est bien supérieure à celle des matériaux de structure traditionnels, ce qui le rend particulièrement adapté aux ponts supportant des charges dynamiques. Grâce à ses caractéristiques, le pont composite améliore l'adaptabilité des systèmes de transport et revêt une importance capitale pour nos applications pratiques et notre développement actuels.

4. Excellente résistance sismique

Grâce aux excellentes propriétés mécaniques des matériaux composites, la taille des éléments, le poids propre de la superstructure et la force d'inertie en cas de tremblement de terre peuvent être réduits, ce qui améliore la résistance aux tremblements de terre. Parallèlement, la capacité sismique du pont composite est encore améliorée grâce à sa grande capacité portante. De plus, sa légèreté lui confère des avantages significatifs en termes de restauration et de reconstruction rapides après un tremblement de terre, notamment en cas de circulation difficile. Les avantages du pont composite en zone sismique sont donc particulièrement importants.

5. Possibilité de réaliser une plus grande portée

La construction de ponts à très grande portée est essentielle au progrès humain et au développement économique. L'acier et le béton ayant un poids propre plus important et une résistance limitée, l'influence de ce poids propre augmentera avec l'augmentation de la portée. Les structures et matériaux traditionnels auront du mal à répondre aux besoins des grandes portées. Grâce à ses avantages en termes de résistance, de légèreté et de résistance à la corrosion, le PRF est considéré comme un matériau idéal pour la réalisation de structures de grande portée. Bien qu'il n'en soit encore qu'au stade de la recherche, le pont à très grande portée constituera un axe de développement important pour ce type de pont. Le développement et l'application du PRF conventionnel constituent le fondement du pont à très grande portée.