| Classification | Méthodes de mise en œuvre et principes de renforcement | Avantages | Limites | Application |

Renforcement de la couche superficielle en béton armé | Le coffrage de support est coulé en place ou en béton projeté, et une couche mixte d'acier est ajoutée à l'extérieur du composant, des barres d'armature sont ajoutées pour augmenter l'interface des composants. | Améliore considérablement la capacité portante, la ductilité et la rigidité, l'effet fiable, la qualité d'ingénierie et la durabilité faciles à contrôler. | La période de construction est longue, l'utilisation normale de la structure est restreinte et l'environnement humide n'est pas bon. | Gamme plus large |

Renforcement du mortier de béton armé avec couche de surface | Pose de barres d'acier, fixation du treillis métallique et des composants d'origine, enduits en couches et entretien. | Il peut améliorer l'intégrité des composants, la construction simple, le bon effet et la durabilité. | L'ajout de renfort est limité et l'épaisseur de la surface de renfort est limitée. | Colonnes en briques renforcées, murs en briques, etc. |

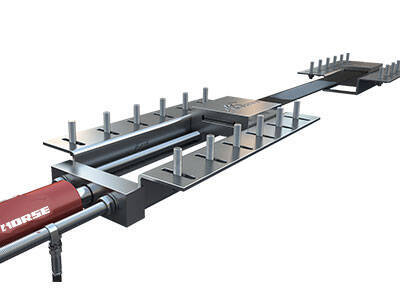

Renfort de gaine en acier | L'enveloppe extérieure du composant est renforcée par un profilé en acier. Selon le liant utilisé, on distingue deux types de composants : sec et humide. | La construction est pratique et les performances sismiques peuvent être améliorées efficacement. | Il convient de prêter attention à la peinture antirouille sur la surface du manchon en acier ou à la protection de surface avec du mortier de ciment. | Il est utilisé pour renforcer les poutres et colonnes en béton armé, les colonnes en briques, les cheminées en briques, etc. |

Renfort en tôle d'acier collée | Utilisation d'un adhésif de collage de plaque d'acier pour coller la plaque d'acier et le composant d'origine afin d'améliorer la capacité portante, la résistance aux fissures et la ductilité des éléments. | La construction est pratique et rapide, et les conditions environnementales du chantier sont bonnes. | La plaque d'acier doit être protégée et la température ambiante ne doit pas dépasser 60 °C. | Éléments généraux de flexion et de traction soumis à une action statique

|

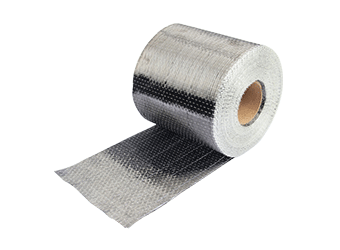

| Renforcement du revêtement FRP | La feuille de fibre de carbone est collée à la surface du composant avec un matériau composite haute performance en résine pour améliorer la capacité portante et la résistance de l'élément structurel. | Module d'élasticité en fibre de carbone et haute résistance, poids léger, petit volume, durabilité et résistance à la corrosion, facile à construire. | L'environnement ne peut pas dépasser 60 degrés C | Composant en béton, structure en acier, structure en bois |