Enveloppe en fibre de carbone pour poutre

Capacité de flexion et de cisaillement insuffisante de la poutre

Grâce à l'analyse de calcul et à l'application technique de la structure en béton renforcée par une enveloppe en PRFC collée, il est démontré que la méthode de renforcement par enveloppe en PRFC est une technologie de renforcement efficace pour la structure en béton.

Étude d'ingénierie

Un projet de construction complet, mené par une société de développement de Nanjing, est situé dans la banlieue est de la ville. Il comporte six étages. Les deux niveaux inférieurs sont des structures à ossature, et les quatre niveaux supérieurs sont des poteaux à ossature de forme spéciale. La surface totale au sol est de 8 000 m². L'étage initialement prévu est un centre commercial, tandis que les deux niveaux supérieurs sont destinés à des logements. Suite à ce changement d'usage, la charge au sol augmente. En fonction de cette augmentation, la structure entière est vérifiée et calculée. Les résultats montrent que la capacité de flexion et de cisaillement des poutres au niveau local du deuxième étage est insuffisante, tout comme la capacité portante en flexion des dalles.

Détermination du schéma de renforcement poutre-dalle

Le bâtiment étant construit et utilisé, les autres étages doivent être en service normal pendant la période de renforcement. Après une comparaison approfondie des schémas (voir tableau 1), il a été finalement décidé d'utiliser une pâte d'enveloppement en fibre de carbone et une méthode de renforcement en acier collé localement.

| Article | Méthodes de renforcement structurel | ||

| Renforcement du PRF | Gainage en acier | Section agrandie | |

| Application | Largement | Limité | -- |

| Poids | Lumière | Plus lourd | Plus lourd |

| Force | Haute résistance | Haut | -- |

| Coordination du renforcement | Bien | Bien | Bien |

Longueur et tour | La longueur est arbitraire et le tour est pratique. | Longueur limitée, connexion soudée | -- |

| Prix | Haut | Haut | Lower |

Durability | Bien | Inférieur | Bien |

Période de construction | Période courte | Période plus longue | Période plus longue |

Difficulté d'opération | Fonctionnement simple | Complexe | Complexe |

| Impact sur le monde extérieur | Petit | Grand | Grand |

Matériau d'armature

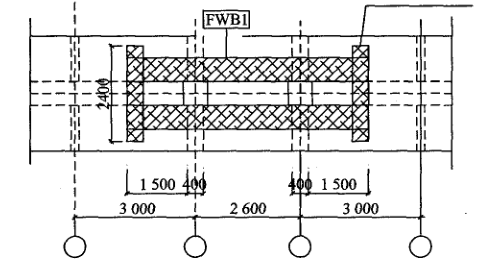

L'acier collé FW B est constitué d'une plaque d'acier Q345 de 4 m, d'une enveloppe renforcée de fibres de carbone de 0,167 m d'épaisseur (soit 300 g/m²) et d'une colle de grade A. Cette colle comprend une colle de fond, un mastic époxy de ragréage et une résine d'accrochage.

Conception des armatures

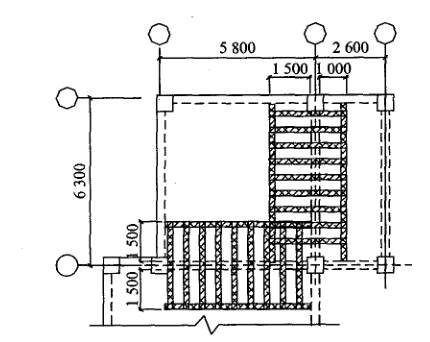

Dans la partie renforcée du deuxième étage, la capacité portante de la courbure négative du plancher doit être augmentée de 25. D'après les calculs et les analyses, la courbure négative du plancher est compensée par l'utilisation d'une enveloppe en PRFC de 200 m de large et de 400 m de long, formant une seule couche de 2 500 m de long. La capacité portante de la poutre Liang Shouwan doit être augmentée de 20 % et trois couches de tissu de fibres Liang Kuan doivent être collées le long de la partie inférieure de la poutre. De plus, des cerceaux en forme de « U » sont collés sur les supports aux deux extrémités de la poutre et des deux côtés de la poutre secondaire pour le renforcement du cisaillement, et un ancrage d'entrée de barre longitudinale de 200 m de large est collé aux deux extrémités des cerceaux en forme de « U ».

Procédé de construction et effet du renforcement

La surface de la plaque d'acier collée sur l'élément en béton doit être inoxydable, et le matériau antirouille doit être inoffensif pour la plaque d'acier et l'adhésif.

Le projet a consisté à coller environ 145 m³ d'enveloppe renforcée de fibres de carbone, réalisé en 15 jours ouvrés. La pâte la plus épaisse est l'arceau en U situé à la base de la poutre, et trois couches d'enveloppe renforcée de fibres de carbone de 0,167 m³ d'épaisseur. Ce procédé n'augmente ni le poids ni les dimensions géométriques de la structure, et répond aux exigences du maître d'ouvrage en termes de délais, d'espace et de qualité de construction. De plus, l'adhérence entre l'enveloppe en PRFC et la surface du béton est intacte, la durabilité est bonne et l'effet de renforcement est remarquable.

Conclusion

L'analyse des calculs et l'application technique de la structure en béton renforcée par une enveloppe en PRFC collée démontrent que la méthode de renforcement par enveloppe en PRFC est une technologie efficace pour le renforcement des structures en béton. Comparée aux technologies de renforcement traditionnelles, la technologie du béton armé enrobé de fibres de carbone présente de bonnes performances économiques globales. Les structures en béton armé de fibres de carbone offrent de vastes perspectives d'application.