Renforcement continu des poutres caisson

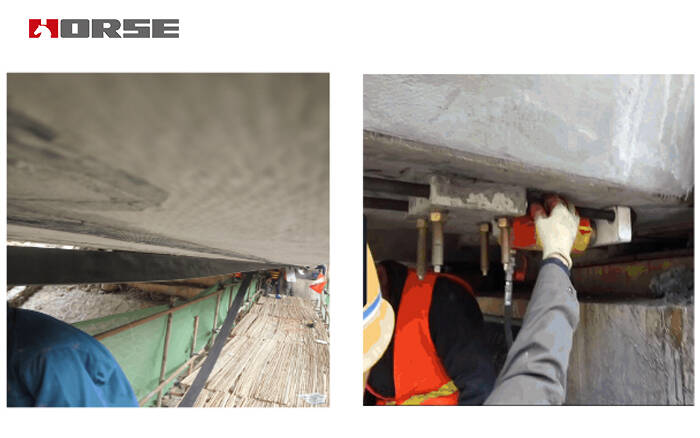

Renforcement du stratifié CFRP précontraint

Selon la répartition des fissures et les caractéristiques de contrainte de la poutre-caisson, des stratifiés CFRP précontraints de 2 pics de 1,4 mm d'épaisseur et de 100 mm de large sont disposés.

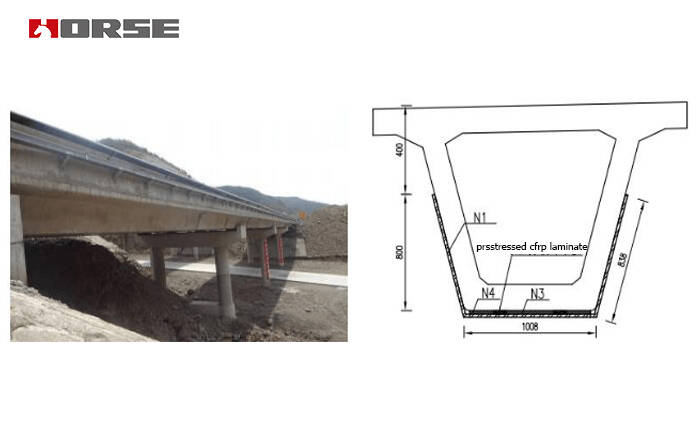

Aperçu du projet

Le pont mesure 86 m de long, 12,5 m de large et 11,5 m de large. Sa portée est de 4 x 20 m. Sa superstructure est constituée d'un caisson continu en béton précontraint assemblé, avec quatre poutres disposées latéralement. La structure inférieure est constituée d'un pilier à colonnes ; le tablier en béton bitumineux est revêtu.

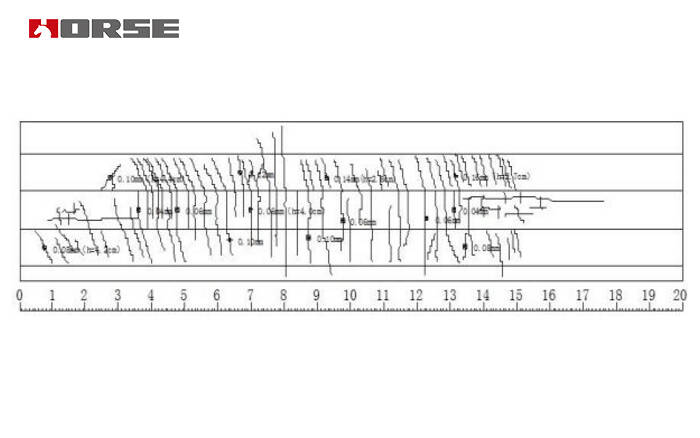

Les principales maladies

On observe 33 fissures transversales et 2 fissures obliques dans le plancher d'une poutre-caisson de 4 à 4 lb, d'une largeur maximale de 0,06 mm. On observe également 27 fissures obliques dans la section transversale de 0,14 mm des piliers de 3 lb, de chaque côté. Dans la section transversale de 3/8 à 5/8 mm des piliers de 3 lb, on observe 19 fissures verticales et 41 fissures obliques, dont certaines s'étendent jusqu'à la semelle, d'une largeur maximale de 0,16 mm.

Test de charge et analyse des maladies

Les essais de charge sur les travées 3 et 4 du pont montrent que le pont ne présente aucune anomalie notable. Compte tenu du contraste latéral entre la déflexion, la déformation et la discrétion des données de la poutre-caisson, la déflexion et la déformation de la poutre-caisson 4-4# sont légèrement supérieures dans la poutre-caisson 4-1# par rapport à la poutre-caisson symétrique lors de l'essai, ce qui indique une légère faiblesse de la rigidité de la poutre-caisson 4-4#.

La poutre-caisson de 4 à 4 lb présente de denses fissures transversales, verticales et obliques. La répartition des fissures révèle que seules les poutres-caissons de 4 à 4 lb parmi les 16 poutres-caissons du pont produisent des fissures, ce qui est rare, et que ces fissures sont principalement réparties au centre de la travée médiane. Les caractéristiques de contrainte de la poutre continue permettent de conclure que ces fissures se sont formées avant la transformation du système structurel. Leur nombre et leur répartition permettent ensuite d'analyser ces fissures, qui sont des fissures de contrainte structurelle. En résumé, on suppose que les fissures dans la poutre-caisson de 4 à 4 lb sont dues à une force de précontrainte insuffisante (perte) ou à une résistance du béton insuffisante pendant la construction.

Schéma de renforcement et technologie de construction

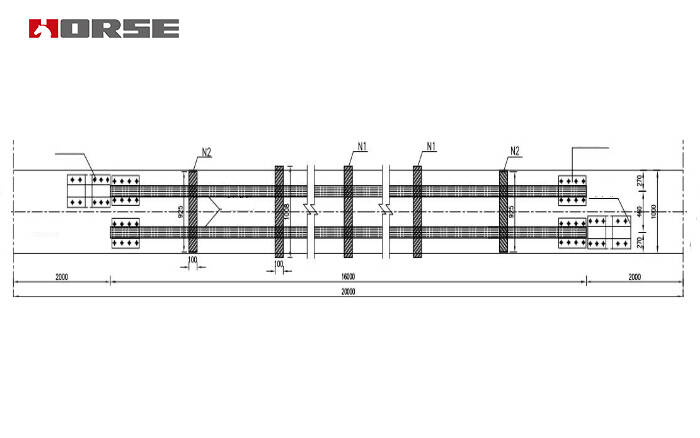

L'envergure du composant est de 20 m. La longueur du stratifié en fibre de carbone est de 16 m.

En fonction de la répartition des fissures et des caractéristiques de contrainte de la poutre caisson, 2 stratifiés CFRP précontraints de 1,4 mm d'épaisseur et de 100 mm de large sont disposés.