Technologie de renforcement sismique

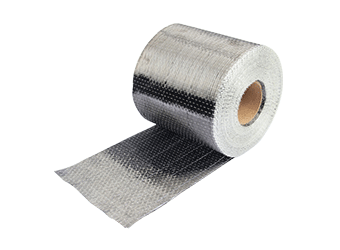

Le renforcement par fibres de carbone collées consiste à coller des feuilles de fibres de carbone sur la surface des éléments en béton à l'aide d'un adhésif. Cette méthode permet d'exploiter pleinement la résistance à la traction des fibres de carbone, remplaçant ainsi les barres d'acier. Elle est principalement utilisée pour renforcer la résistance à la flexion et au cisaillement des éléments en béton.

Principes fondamentaux du renforcement parasismique en Chine

1) Compte tenu de l'état historique des bâtiments existants, les exigences de renforcement parasismique sont légèrement inférieures à celles des nouvelles constructions. Autrement dit, le degré de sécurité du renforcement parasismique peut être réduit de 15 à 30 %, sans toutefois être inférieur à 7 degrés.

2) Une évaluation sismique doit être réalisée avant tout renforcement parasismique, et les bâtiments ne présentant pas de valeur pour ce type de renforcement doivent être démolis en fonction de leur nécessité et de leur rationalité technique et économique.

3) Le renforcement parasismique est particulièrement important pour les ouvrages d'art urbains et les projets d'ingénierie susceptibles de provoquer des catastrophes secondaires.

4) Lors du renforcement, il convient de renforcer l'intégrité de la structure, d'améliorer sa capacité de déformation et de renforcer les maillons faibles et les parties dangereuses.

Objets de renforcement parasismique

1) Les bâtiments et structures n'ayant pas fait l'objet de mesures de renforcement parasismique doivent faire l'objet d'une évaluation de leur performance sismique conformément aux dispositions nationales pertinentes, et les mesures de renforcement parasismique nécessaires doivent être prises.

2) Les bâtiments et structures construits dans des zones bénéficiant de normes de renforcement parasismique améliorées.

3) Les bâtiments et structures endommagés par un tremblement de terre doivent être renforcés afin de rétablir leur état de fonctionnement.

Technologie de renforcement sismique des structures en béton

1) Méthode de section élargie, également appelée méthode de renforcement du béton enrobé, consiste à couler du béton armé neuf à l'extérieur des éléments en béton d'origine pour augmenter la section et le renforcement des éléments de structure, afin d'améliorer la capacité portante et la rigidité de la structure. Cette méthode s'applique aux poteaux, plaques, poutres et autres éléments de structure en béton.

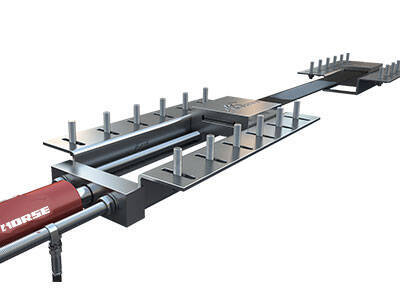

2) Méthode de renforcement par enrobage d'acier : une cornière en acier est enroulée autour de l'élément d'armature afin d'en améliorer la capacité portante. Elle se divise en deux types : l'acier enrobé à sec et l'acier enrobé humide. La méthode de renforcement à sec consiste à enrober directement la cornière en acier autour de l'élément renforcé, ou à la remplir de mortier de ciment, sans toutefois garantir une transmission efficace du cisaillement à la surface du joint. La méthode de renforcement humide consiste à laisser un espace entre la cornière et les éléments renforcés, lequel est comblé par du mortier de ciment au latex ou de la colle structurale injectée. Cette méthode permet d'améliorer considérablement la capacité portante, la ductilité et la rigidité des éléments sans modifier la section. La méthode d'armatures enrobées est applicable aux poteaux et poutres en béton.

3) Modification de la méthode de renforcement du système de force. L'ajout d'éléments de force latérale structurelle, tels qu'un mur parasismique en béton, des contreventements en acier, etc., modifie le mode de contrainte de la structure sous séisme. La majeure partie de l'action sismique sera transférée au nouveau mur parasismique et au support en acier, tandis que les éléments structurels d'origine en supporteront une faible partie. Leur capacité portante initiale répondra ainsi aux exigences sismiques, renforçant ainsi la structure d'origine.

4) La méthode de renforcement par collage consiste à coller de fines plaques d'acier à la surface des éléments en béton avec un liant (adhésif structural), afin de les lier ensemble. Elle est principalement utilisée pour renforcer la résistance à la flexion et au cisaillement des éléments en béton. Elle est également utilisée pour l'ouverture des murs de refend en béton.

5) La méthode de renforcement par collage de tissus en fibre de carbone est similaire à celle des plaques d'acier. Elle consiste à coller des feuilles de fibre de carbone à la surface d'éléments en béton à l'aide d'un adhésif, optimisant ainsi la résistance à la traction de la fibre de carbone et remplaçant ainsi les barres d'acier. Elle est principalement utilisée pour renforcer la résistance à la flexion et au cisaillement des éléments en béton. Elle peut également être utilisée pour le renforcement ductile des poteaux structurels.