Renforcement et modernisation des éléments en béton armé

Les éléments en béton armé présentent des déformations ou des dommages après un certain nombre d'années. Certains bâtiments ou structures sont utilisés au-delà de leur limite d'utilisation, ou encore en raison d'une mauvaise qualité de construction. Dans ce cas, il est souvent difficile de les démolir et de les reconstruire pour des raisons de qualité ou de durée de vie. Pour continuer à être utilisés, les bâtiments doivent être renforcés, reconstruits et réparés.

Les éléments en béton armé présentent des déformations ou des dommages après un certain nombre d'années. Certains bâtiments ou structures sont utilisés au-delà de leur limite d'utilisation, ou encore en raison d'une mauvaise qualité de construction. Dans ce cas, il est souvent difficile de les démolir et de les reconstruire pour des raisons de qualité ou de durée de vie. Pour continuer à fonctionner, la construction doit être renforcée, reconstruite et réparée. Les méthodes de renforcement et de reconstruction des structures en béton armé ont leurs propres caractéristiques.

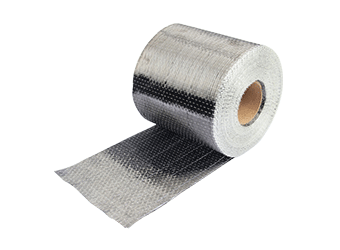

Le renforcement et le renforcement du renforcement des fibres externes sont un matériau de cimentation en résine, qui est attaché à la région de traction du composant renforcé pour fonctionner avec la section renforcée, de manière à atteindre l'objectif de renforcement et de renforcement des éléments structurels et d'amélioration des propriétés mécaniques structurelles.

La méthode de renforcement par appui consiste à réduire la portée de calcul de l'élément en flexion en ajoutant un point d'appui, réduisant ainsi le moment de flexion sur l'élément renforcé et répartissant sa capacité portante. Selon les propriétés mécaniques des éléments porteurs, on distingue deux types de renforcement : le point d'appui rigide et le point d'appui élastique.

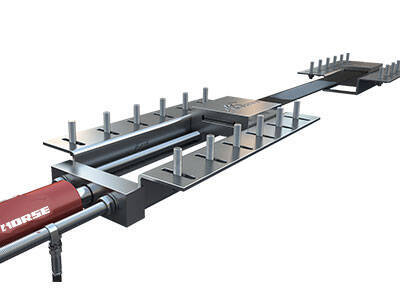

L'armature en acier sous-traité consiste à renforcer les quatre ou deux angles de l'acier renforcé (généralement des cornières ou des profilés en U) ou les plaques d'acier du composant renforcé. La poutre en béton armé de l'acier sous-traité est également appelée armature en acier sous-traité humide. Pour renforcer les éléments en béton, cette méthode consiste à utiliser une colle époxy pour remplir l'acier et l'armer. Le composant est alors assemblé pour garantir l'intégrité de la structure en acier et du composant d'origine.

L'armature des éléments de flexion en béton armé est constituée d'une plaque d'acier à haute résistance dans la partie manquante de la capacité portante de l'élément (section positive, section transversale comprimée ou section oblique). Elle applique une nouvelle force à l'ensemble béton armé-plaque d'acier, renforce la déformation du béton et renforce l'élément renforcé. Les propriétés de flexion, de cisaillement et de compression de la plaque d'acier sont optimisées, évitant ainsi la concentration de contraintes dans les éléments en béton armé, ce qui renforce le procédé.

Dans la zone de compression d'un élément de compression en béton armé, une couche de béton coulé sur place est ajoutée pour augmenter la hauteur effective de la section, agrandir sa surface et ainsi améliorer sa résistance à la flexion, sa résistance au cisaillement et sa rigidité globale, tout en jouant un rôle de renforcement. La méthode d'élargissement du renforcement de la section doit tenir compte de l'interface entre la nouvelle pièce et la pièce d'origine afin de former un tout.