Renforcement des poutres-caissons

Stratifié CFRP précontraint

Le système de renforcement en PRFC précontraint est l'une des rares méthodes de renforcement actif permettant un renforcement sans décharge. Une fois terminé, il participe efficacement au système de contrainte de la structure, accroît sa résistance et sa rigidité, réduit sa déflexion et sa déformation, et limite et scelle les fissures.

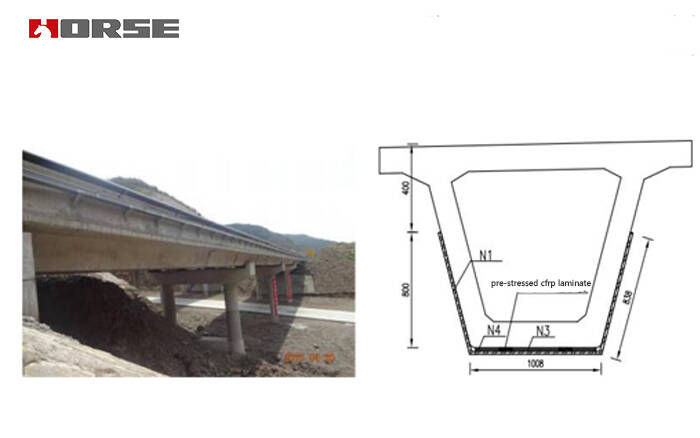

Aperçu du projet

Le pont mesure 86 m de long et 11,5 m de large, soit 12,5 m de large. La portée est de 4 x 20 m. La superstructure est constituée de poutres-caissons continues préfabriquées en béton précontraint, dont quatre poutres sont disposées transversalement. La partie inférieure est constituée d'un pilier en colonnes et le tablier est en béton bitumineux.

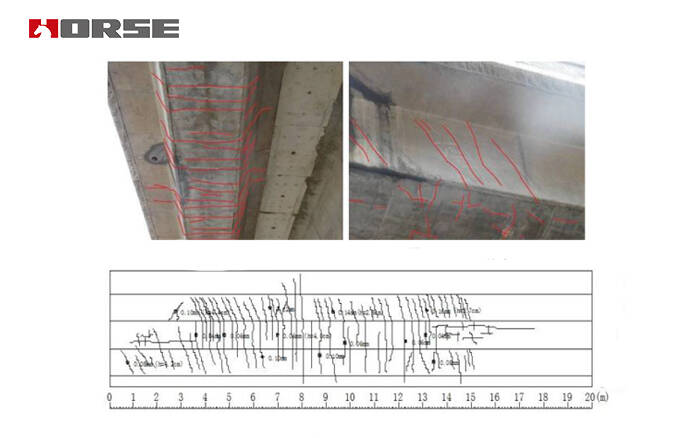

Principales maladies

Il y a 33 fissures de poutres caissons de 4 à 4# et 2 fissures obliques, la largeur maximale des fissures de 0,06 mm, à partir du pilier 3# 0-1/4 des deux côtés de la plage transversale de l'âme, la répartition totale de 27 fissures obliques, à partir du pilier 3# 3/8-5/8 sur toute la plage, il y avait 19 fissures verticales et 41 fissures obliques, les fissures s'étendant jusqu'à la partie de la bride la largeur maximale de 0,16 mm.

Test de charge et analyse des maladies

Les essais de charge sur les travées 3 et 4 du pont montrent qu'il n'y a aucune anomalie évidente lors de l'essai de charge du pont.

À l'aide de la déflexion, de la déformation et des données discrètes de comparaison horizontale des poutres-caissons 4-1# et 4-4#, la déflexion et la déformation des poutres-caissons 4-1# et 4-4# lors du processus d'essai sont légèrement plus importantes, ce qui indique la rigidité des poutres-caissons 4-4#.

La poutre-caisson de 4 à 4 lb présente de nombreuses fissures transversales, verticales et obliques. La répartition de ces fissures indique que le pont 16

Seules les poutres-caissons de 4 à 4 lb présentent des fissures, qui sont ponctuelles et principalement réparties au centre de la travée médiane. Les caractéristiques de contrainte d'une poutre continue de même portée suggèrent que les fissures se forment avant la transformation du système structural. Leur nombre et leur répartition indiquent qu'il s'agit de fissures de contrainte structurelle.

En résumé, on en déduit que les fissures dans la poutre-caisson 4-4# sont dues au manque de précontrainte réelle (perte), ou que la résistance du béton n'est pas à la hauteur de la résistance de conception.

Schéma de renforcement et technologie de construction

Selon la conception des éléments de type A en béton précontraint partiel, la poutre-caisson présente des fissures de contrainte structurelle plus intenses, qui ne sont pas conformes aux spécifications actuelles, et présentent un certain degré d'affaiblissement de la capacité portante et de la rigidité de la structure, ce qui affecte la sécurité structurelle.

1 en cas de rigidité insuffisante, la plaque de carbone précontrainte est utilisée pour renforcer.

2 compte tenu de la portée du composant de 20 m, la longueur de la plaque de carbone est conçue pour être de 16 m.

3 selon la répartition des fissures et les caractéristiques de contrainte de la poutre caisson, 2 plaques de carbone précontraintes de 1,4 mm d'épaisseur et de 100 mm de large sont disposées et la force de traction est de 1200 MPa (16,8 t).

En résumé

Le système de renforcement en PRFC précontraint est l'une des rares méthodes de renforcement actif permettant un renforcement sans décharge. Une fois terminé, il participe efficacement au système de contrainte de la structure, augmente sa résistance et sa rigidité, réduit sa déflexion et sa déformation, et réduit et scelle les fissures. L'utilisation de fibres de carbone

Ce matériau se caractérise par sa légèreté, sa résistance élevée et sa résistance au vieillissement. Après renforcement, il est quasiment inerte et ne présente aucun volume. C'est une solution idéale pour le renforcement des ponts.