Schéma de maladie et de renforcement d'un pont à poutres en T à

Tissu en polymère renforcé de fibres (FRP)

Le tissu polymère renforcé de fibres (FRP) présente une grande fiabilité et peut améliorer la capacité de flexion de la poutre principale et prolonger la durée de vie de la poutre en T.

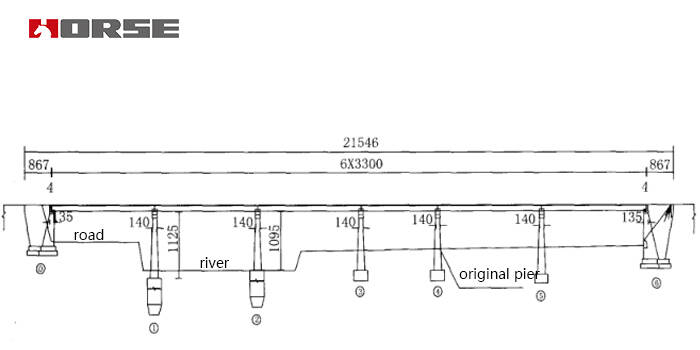

Aperçu du projet

Le pont a été construit dans les années 1960 et sa partie supérieure est constituée de poutres en T précontraintes à appui simple. Pendant de nombreuses années, la charge de conception du pont d'origine n'a pas pu répondre aux exigences du développement du trafic. La liaison latérale de la poutre en T s'est affaiblie. La force exercée sur la poutre unique est supérieure à la charge de conception d'origine, ce qui a entraîné sa fissuration, compromettant gravement la durabilité et la sécurité de fonctionnement de la structure.

Statut de la maladie

La résistance du béton du pont est faible, les fissures dans la poutre sont abondantes, les armatures locales sont corrodées et l'eau est gravement endommagée. Compte tenu de la situation actuelle en matière d'inspection, la maladie a réduit la capacité de réserve de sécurité structurelle.

Le revêtement du tablier du pont est gravement endommagé et présente de nombreuses fissures. En fonctionnement, les vibrations du tablier sont plus importantes, les appuis sont endommagés et certaines poutres présentent un léger tassement et une déflexion plus importante.

La maladie actuelle des ponts montre que la durabilité du pont est devenue un problème majeur limitant son utilisation, et la détérioration de la fonction du pont est entrée dans une période accélérée.

Le pont devrait connaître une circulation plus dense. Avec l'achèvement des travaux de reconstruction, les caractéristiques d'un trafic dense apparaîtront progressivement.

Cause de la maladie

Étant donné que la charge de conception du pont d'origine correspond à l'ancienne norme, elle est inférieure à la nouvelle norme. De plus, le trafic lourd sur la route est important, ce qui entraîne un phénomène de surcharge. L'effet des véhicules dépasse la charge de conception initiale de la poutre en T d'origine.

La connexion des poutres en T et des poutres est rouillée ou endommagée, la connexion latérale des poutres en T est affaiblie et la rigidité latérale des ponts est relativement faible.

L'épaisseur du tablier du pont d'origine est faible, il est difficile de résister à l'impact du véhicule, provoquant la défaillance de la chaussée et la défaillance de la fonction d'étanchéité de la surface du pont, ce qui provoque la fuite d'eau au bas du pont, accélère le vieillissement du béton de la poutre et provoque la corrosion de la barre d'acier dans la poutre.

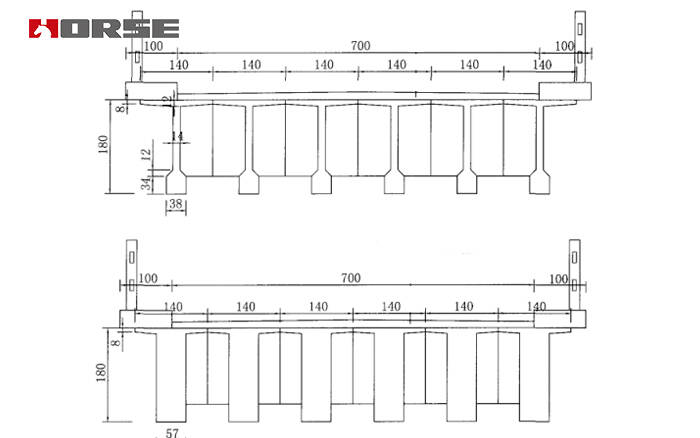

Schéma de renforcement : renforcement du tissu FRP

La couche de surface et le revêtement en béton du tablier d'origine sont ciselés. Les fissures d'une largeur inférieure à 0,15 mm sont traitées par scellement superficiel, puis scellées avec de la colle époxy. Pour les fissures supérieures à 0,15 mm, la méthode de réparation par injection sous pression (injection sous pression d'une colle de réparation à faible viscosité et haute résistance dans la cavité de la fracture) a été utilisée.

Dérouillage, réparation et brossage de peinture antirouille pour les plaques d'acier de liaison entre les poutres en T d'origine.

La poutre en T d'origine est implantée avec de l'acier, puis sa surface supérieure est ciselée, nettoyée et brossée, puis du béton de flexion C40 de 15 cm d'épaisseur est coulé. Le béton est constitué de deux couches de treillis métallique, relié à la barre d'acier encastrée dans la poutre en T.

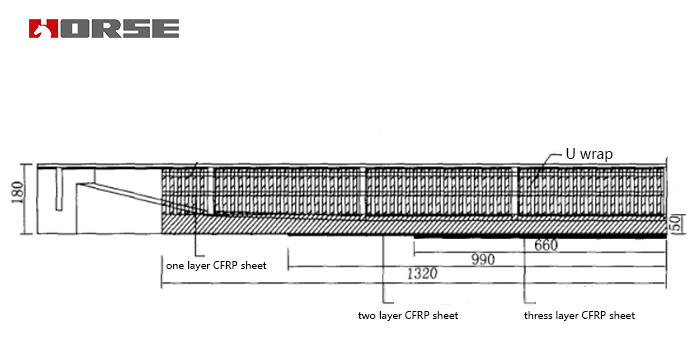

Le liant époxy est utilisé pour coller le tissu FRP au bas de la poutre en T d'origine du pont afin d'améliorer la résistance à la traction de la travée et d'élever la capacité portante de la poutre au niveau de la route de catégorie I. La poutre en T est centrée au milieu du pont. Un tissu FRP est fixé sur une longueur de 0,8 fois la poutre longitudinale, une deuxième couche de tissu FRP sur une longueur de 0,6 fois la poutre et une troisième couche de tissu FRP sur une longueur de 0,4 fois la poutre.